If you’re forecasting for the next crude oil project, you’ve come to the right place. One of the most important things to do in this stage is to determine whether the environment you're going to be working in is going to be sweet, or if it’s going to be sour. The term's "sweet" and "sour" refer to how toxic/corrosive the oil is. This helps you in determining which type of equipment you’re going to want to purchase beforehand in order to combat the corrosive environments that sweet/sour crude oil can bring. One of the main pieces of equipment you’ll need to decide this for is slicklines/wirelines in order to have a safe and efficient extraction process. Click here to see what kind of slicklines we offer or continue reading below to figure out how exactly one would determine whether their oil is sweet or sour.

So, how do we go about determining this?

Well, the oil you’re mining may contain a lot of impurities such as heavy metals, waxes, salts, etc. however, sulfur is the one you want to pay close attention to. If the crude oil contains less than 0.5% sulfur, then it is considered sweet. Anything higher than 0.5% sulfur would be considered sour. This sulfur is typically in the form of foul-smelling hydrogen sulfide (H₂S) gas. Because hydrogen sulfide is toxic and highly corrosive, sour crude is more expensive to refine and requires the use of corrosion-resistant equipment. (1) This equipment can prevent the materials from cracking or becoming damaged. If your slickline becomes corroded, cracked, or damaged you are in danger of wasting time and money. Save time, money, and frustrations by choosing a corrosive-resistant slickline.

While we know H₂S gas can be detrimental to the quality of your slicklines, so can other factors. We've taken that into consideration and came out with our brand new Materials Guide, a system to assist in selecting the most appropriate corrosion-resistant alloy material for oil and gas applications.

Where can I get corrosion-resistant equipment?

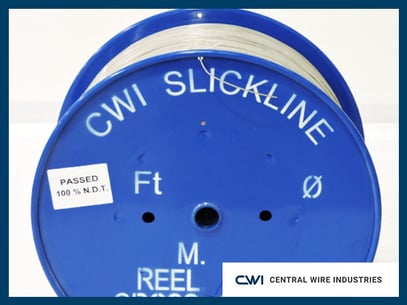

Luckily, at Central Wire we carry just what you need. Our slicklines are manufactured from alloys designed to survive in the harsh and corrosive conditions that exist in oil, gas, and geothermal conditions, both on-shore and off-shore. Each slickline comes with a certificate of conformance that states physical and mechanical properties, including alloy chemistry and breaking load. Every line can be verified by an independent lab to EN10204 standards. Get yours now to ensure your project goes as smooth as planned.

Now that you know how to determine if your oil is sweet or sour and why this is so important, you can get started on choosing the right slickline for you at https://www.slicklines.com/

Here’s an example of some corroded wirelines, don’t let this happen to you:

Instead, ensure your time, money, and safety with GD™ – SUPA® slicklines.

.