Where Can I Use Fine Wire?

Central Wire Industries produces a full line of stainless steel, nickel, copper, and specialty alloy fine wire/ultra fine wire. Tailored to meet your specifications, we're able to produce sizes from: 0.001” (0.0254 mm) up to .032” (0.0812mm) (other sizes by request). Tempers range from soft annealed to spring temper. We also offer a wide range of packaging options from specialty bobbins to bulk packages.

With that being said, our variety of alloys and adaptability to different specifications correlates well with a variety of applications, including but not limited to:

With that being said, our variety of alloys and adaptability to different specifications correlates well with a variety of applications, including but not limited to:- Medical

- Aerospace

- Music

- Electronics

- Oil & gas

- Marine

- Construction

- Petrochemical

- Automotive

- Manufacturing

But what kind of things require fine wire within these different industries?

In this post, we'll explore how our fine wire is essential in the Medical, Aerospace, and Music industry.

Medical

Medical

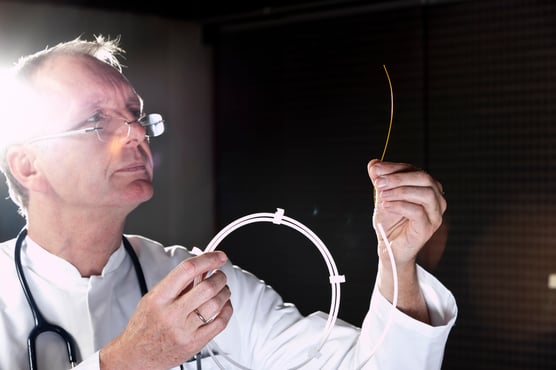

Equipment for the medical industry requires extremely fine and accurate internal wiring for the tool to function properly and operations to go over smoothly. Our fine wire is designed to withstand sterilization methods, is extremely flexible, versatile, and can endure long periods of heavy usage. With CWI's state-of-the-art machinery, we can make wire with unmatched precision. The wire is then tested to be 100% sure that it meets our customer's expectations.

We make fine wire to be used in implants, probes, neural prosthesis, muscle stimulation, pain control, cardiac equipment, catheters, and more. The list goes on and on as more innovative technology is being introduced to the industry day by day.

Round, flat, core, braiding, and staple wires are commonly used in medical technology. Each application is meant for different equipment and CWI can help you select the proper wire type for your operation. Visit our site for inquiries.

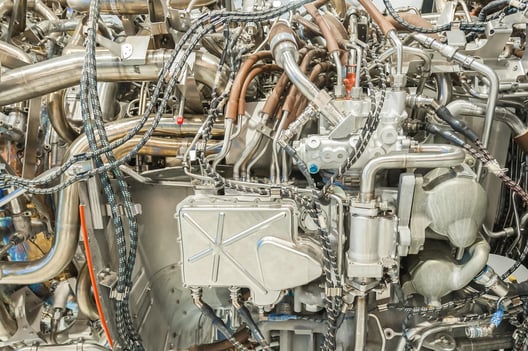

Aerospace

As pictured on the right, there are many different uses for fine wire in the aerospace industry. Some of the main ones are communication, probes, navigation, flight controls, collision avoidance, and weather systems. All require exacting fine wire to make this kind of sophisticated machinery work seamlessly. At CWI we can ensure the quality of the products you need.

We offer a wide range of alloys such as stainless, nickel, copper, zinc, and even specialty alloys that can be found here.

If you're ever unsure of what you need, our long-standing sales team can help assist you!

Contact us now at https://centralwire.com/contact/.