Demister Pads: What Do You Call Them?

Mistex Pad

Mist Eliminator

Mist Extractor

Demister

Demister Pad

Mesh Pad

Something else?

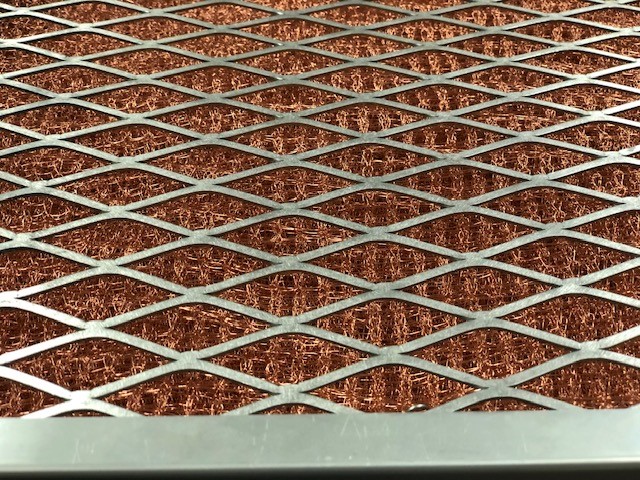

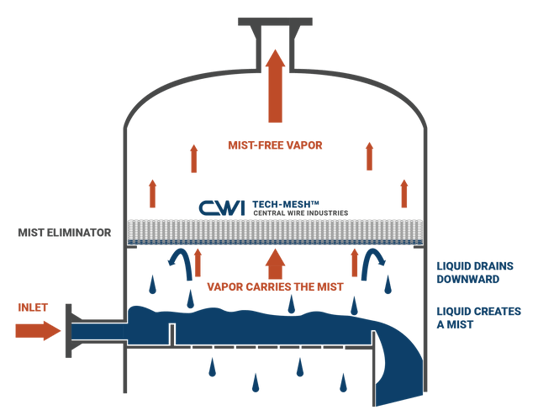

No matter what you call it, all of these names are synonymous terms for the same thing— Knitted Wire Mesh that eliminates liquid entrainment from gas streams. CWI Tech-Mesh™ is knitted on state-of-the-art equipment under strict quality control processes to provide a winding path and a large surface area for the droplets entrained in the gas stream, maximizing gas/liquid separation efficiency and minimizing pressure drop. This low-cost method helps prevent damage and product loss within the facility, cutting operation expenses down more than you may forecast. CWI Tech-Mesh™ Demister Pads are used in many industries including food, agriculture, building and construction, aerospace, mining, and especially the oil and gas industry for their refinery tower internals. Central Wire manufactures Mist Eliminator coalesces in a wide range of wire diameters, alloys, mesh densities, and product geometries under precise production and processing equipment capabilities. We produce the core products for our demister pads in-house that comprise the final product including wire, support rods, and welding wire. If you are looking for high-quality, highly customizable demister pads, get a quote from Central Wire Industries to ensure your order is completed to your standards. Read on to learn more about the benefits, functions, and applications.

- Demister Process Applications

- Gas-Liquid Separators

- Distillation Equipment

- Scrubbers, Process Absorbers, and Precipitators

- Chemical Separators and Extractors

- Oil and Gas Processing Equipment

- Combustion Gas Scrubbers

- Knockout Drums and Receivers

- Refinery Towers

- Liquid-Liquid Coalecers

- Pollution Control Equipment

- Two-Phase Eliminators

- Liquid Entrainment for Compressor Equipment

- Product Recovery Systems

If you need stainless steel, copper, or specialty alloy, we have it in stock. We are established as a high-end, custom demister pad supplier in the United States, United Kingdom, and Canada. Come visit Central Wire Industries’ website devoted to bulk mesh and finished mist eliminators for oil and gas industries. Whether you are performing routine maintenance for turnaround season, installing a new tower, or upgrading your tower internals, rely on the trusted quality of CWI Tech-Mesh™ to get the job done right. Visit our site for information about our alloys, applications, technical resources, and product configurations.