Demister Pads: Functions, Uses, & Benefits

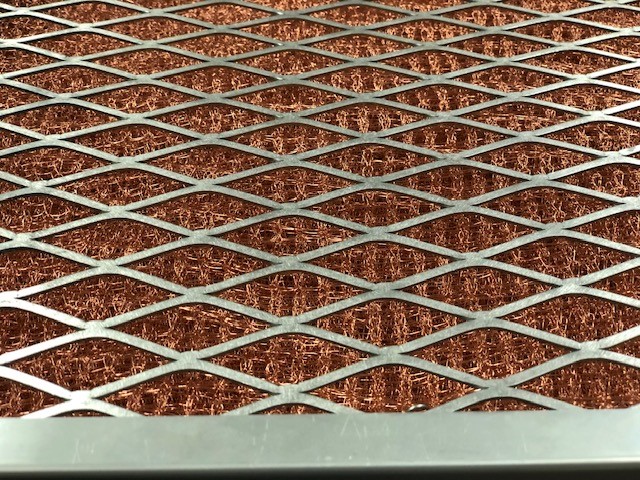

Our CWI Tech-Mesh™ can be used in many industries, including oil and gas, food, agriculture, building and construction, aerospace, and mining. CWI makes coalesces for refineries, filtration systems for environmental concerns, and ventilation for HVAC systems, indoor pools, and restaurants. However, only the correct demister pad can potentially increase your profits via their profound efficiency. Meeting exact customer product dimensional, ductility, and performance/ turnaround specifications requires specialized alloy selection and engineered manufacturing. CWI Tech-Mesh™ mist eliminators/demister pads can be manufactured in a wide range of wire diameters, alloys, mesh densities, and product geometries under precise production and processing equipment capabilities. We produce the core products for our demister pads in-house that comprise the final product including wire, support rods and welding wire.

what is a demister pad?

Demister pads are a specialized knitted wire mesh often used to control air pollution. It traps and manages potentially hazardous mist, while still allowing clean vapor to rise. From oil mist to sulfuric acid, CWI Tech-Mesh™ helps manage toxic material without inhibiting processing efficiency. With the ability to process a wide range of liquids, our stainless steel and specialty alloy pads can assist with chemical processing, water treatment, and more. Demister pads/mist eliminators require little maintenance, have no moving parts, and withstand exposure to corrosive environments. This is why they are a staple within refinery towers.

Mist eliminators are customized specifically to meet each customer’s specifications and equipment geometry. Mist eliminators are configured to ensure minimum liquid entrainment at maximum flow conditions. CWI Tech-Mesh™ demister pads are engineered and fabricated for specific process conditions. Densities typically range from 5.0 to 12.0 lb/ft3. The industry standard size wire for mist eliminators is 0.011 inches (0.28 mm).

How do demister pads work?

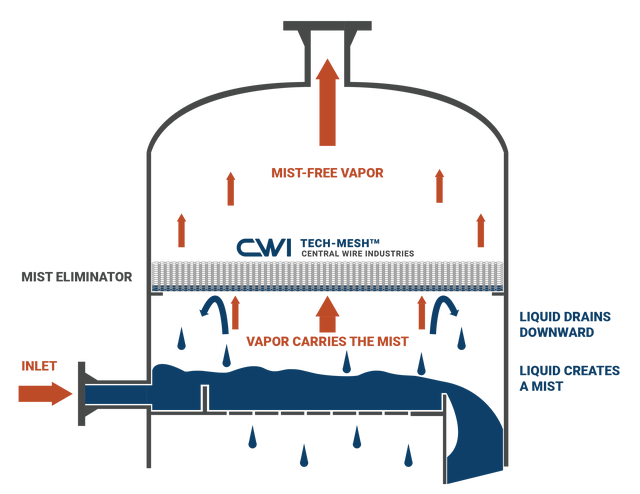

Mist removal, or elimination, is a critical process in many industrial applications. Petrochemical processing, environmental protection, and refinery operations all rely on the separation of liquid droplets from vapor streams to maintain and protect equipment, filter pollution, and operate at peak performance. Mist eliminators, also referred to as demister pads or wire mesh pads help achieve this filtration reliably, efficiently, and with minimal maintenance. They are typically fitted just below tank outlets and can be installed either vertically or horizontally, depending on the configuration of the unit.

As its name implies, mist eliminators remove moisture from gas streams. Vapor carries mist as it rises, and while gas is free to pass through knitted mesh unobstructed, individual mist droplets become trapped. Droplets grow in size as moisture accumulates, eventually causing the heaviest ones to fall back into the pool of liquid below. This coalescing process prevents even small drops of liquid from rising to the top of the tank.

Benefits of demister Pads

- Available in a wide range of alloys, densities, and geometries.

- Corrosion resistant and durable.

- Efficient and reliable filtering process.

- Lightweight sections are easy to install.

- Long service life.

Where can I get a demister pad?

We have the products you need-- www.cwitech-mesh.com. We are established as a high end, custom demister pad supplier in the United States, United Kingdom, and Canada. Come visit Central Wire Industries’ website devoted to bulk mesh and finished mist eliminators for oil and gas industries. Whether you are performing routine maintenance for turnaround season, installing a new tower, or upgrading your tower internals, rely on the trusted quality of CWI Tech-Mesh™ to get the job done right. Visit our site for information about our alloys, applications, technical resources, and product configurations.